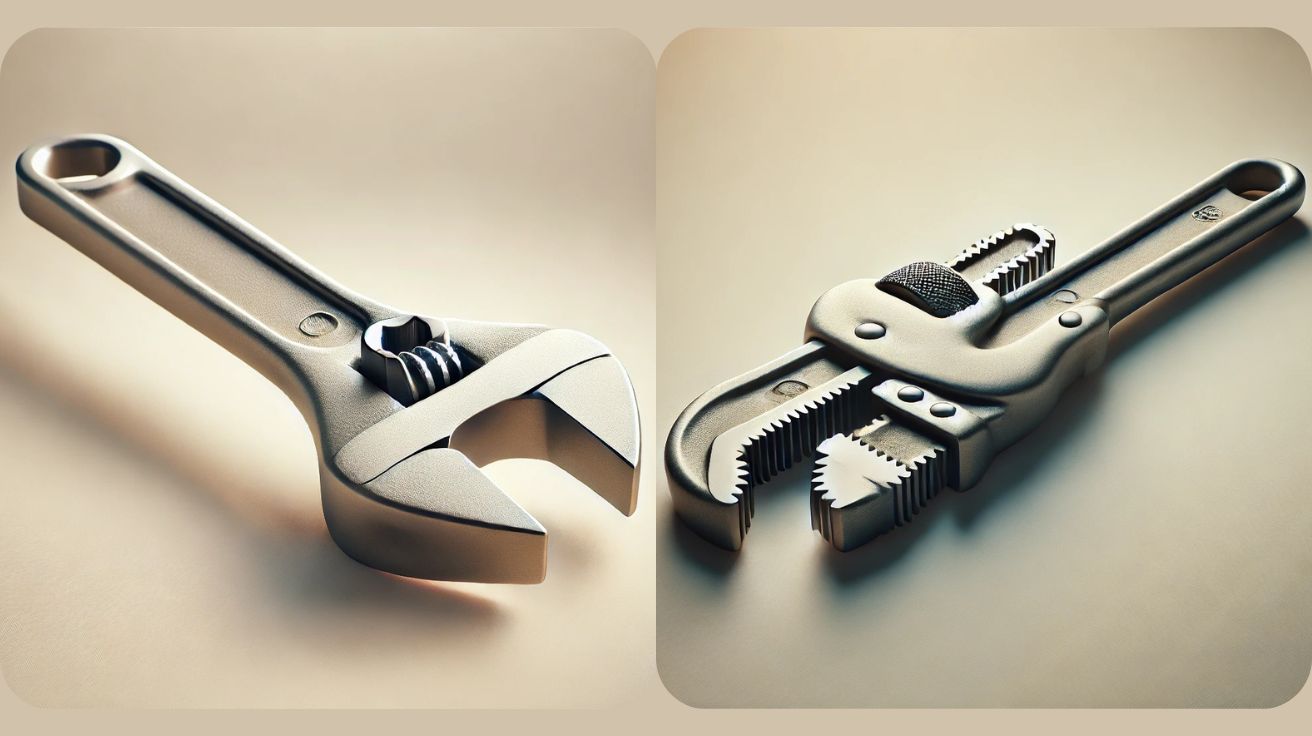

When it comes to hand tools, wrenches are indispensable for both professional tradespeople and DIY enthusiasts alike. Among the many types available, a spud and a pipe wrench are two popular choices that often cause confusion due to their similar appearance.

However, despite some overlapping characteristics, these tools are designed for distinctly different tasks. In this comprehensive guide, we’ll explore what sets a spud wrench apart from a pipe wrench, delve into their unique features, and offer tips on how to select the right one for your project needs.

Understanding the Basics of Wrenches

Wrenches have been a cornerstone of mechanical and plumbing work for generations. Their primary function is to provide leverage and grip, enabling users to fasten or loosen nuts, bolts, and pipes.

Each type of wrench is designed with a specific application in mind—ranging from high-torque tasks to delicate adjustments. By understanding the basics of these tools, you can make an informed decision about which one will serve you best.

Why Choosing the Right Wrench Matters?

Selecting the right wrench not only ensures efficiency but also promotes safety on the job. Using the wrong tool can lead to stripped fasteners, damage to the workpiece, or even personal injury. That’s why distinguishing between a spud wrench and a pipe wrench is important, especially when the task at hand requires precision and a proper fit.

What Is a Spud Wrench?

A spud wrench is a specialized tool that finds its primary use in mechanical and maintenance applications. Here’s everything you need to know about it:

Design and Construction

- Shape and Build: A spud wrench typically features a flat, spade-like head with a relatively narrow jaw. This design allows for a precise grip on bolts and nuts, making it ideal for applications that require careful adjustments.

- Materials: Most spud wrenches are made from high-quality steel to ensure durability and resistance to wear. Some models might include ergonomic handles for added comfort during prolonged use.

- Size Variations: Spud wrenches come in various sizes to accommodate different bolt heads. Whether you’re working on small machinery or larger industrial equipment, there’s likely a spud wrench designed for your specific needs.

Common Uses

- Automotive Maintenance: Spud wrenches are often used in auto repair shops for tasks that require precision, such as adjusting small fasteners or working in tight spaces.

- Machinery Repairs: In industrial settings, these wrenches are used to tighten or loosen bolts on heavy machinery where a firm but delicate touch is necessary.

- Electrical Installations: Their design also makes them suitable for electrical work where precision is paramount and delicate components are involved.

Advantages of a Spud Wrench

- Precision: Its slim design allows for a tight grip on fasteners, minimizing the risk of slipping.

- Versatility: Although it is specialized, the spud wrench’s design makes it a good choice for various applications where small, precise adjustments are needed.

- Ease of Use: Lightweight and ergonomic, these wrenches reduce user fatigue during prolonged tasks.

In summary, the spud wrench is best suited for tasks that require precision and care. Its design minimizes damage to fasteners and is perfect for environments where space is limited and accuracy is key.

What Is a Pipe Wrench?

In contrast to the spud wrench, the pipe wrench is a more robust tool, primarily used in plumbing and heavy-duty applications.

Design and Construction

- Shape and Build: The pipe wrench is characterized by its adjustable jaw mechanism and serrated teeth. This design is intended to grip cylindrical objects firmly, such as pipes, even when they are wet or greasy.

- Materials: Pipe wrenches are generally constructed from heavy-duty materials like forged steel. The durability of these wrenches makes them ideal for tasks that involve a lot of force.

- Adjustability: One of the key features of a pipe wrench is its adjustable jaw. This allows the tool to accommodate pipes of various diameters, making it incredibly versatile for plumbing tasks.

Common Uses

- Plumbing: The pipe wrench is a staple in plumbing. Its design allows plumbers to grip and turn pipes with ease, making it indispensable for assembling and disassembling pipe connections.

- Construction: In construction settings, these wrenches are used for tasks that involve the manipulation of large pipes and fittings, such as during the installation of water or gas lines.

- Heavy-Duty Repairs: The robust construction of a pipe wrench also makes it useful in industrial repair jobs where significant torque is required.

Advantages of a Pipe Wrench

- High Torque Capability: The pipe wrench’s design is optimized to deliver the high torque necessary to loosen or tighten pipe connections securely.

- Versatility: With its adjustable jaw, it can be used on a wide range of pipe sizes and types.

- Durability: Made from heavy-duty materials, pipe wrenches are built to last even under the stress of frequent heavy use.

The pipe wrench is an essential tool for any job that involves pipes and heavy-duty connections. Its design ensures that it can handle high-torque applications where a secure grip is critical.

Comparing the Two: Key Differences

While both (a spud and a pipe wrench) are designed to provide leverage and grip, they are optimized for very different tasks. However, an impact wrench is designed for high torque and fast work, making it ideal for car repairs and quickly loosening bolts.

Let’s talk about the key differences between them:

1. Purpose and Application

- Spud Wrench:

- Primary Use: Best suited for precision work such as automotive repairs, machinery maintenance, and delicate adjustments.

- Ideal For: Small fasteners, bolts, and nuts where precision and a careful grip are required.

- Pipe Wrench:

- Primary Use: Designed primarily for plumbing and heavy-duty applications involving pipes.

- Ideal For: Gripping and turning pipes, fittings, and connections that require significant torque.

2. Design Features

- Jaw Design:

- Spud Wrench: Typically features a flat, narrow jaw designed for precision.

- Pipe Wrench: Comes with serrated, adjustable jaws that provide a strong grip on round objects.

- Adjustability:

- Spud Wrench: Generally non-adjustable, as it is made for a specific size and type of fastener.

- Pipe Wrench: Equipped with an adjustable jaw, allowing it to fit pipes of various diameters.

3. Materials and Durability

- Spud Wrench:

- Materials: Usually made from high-quality steel with an emphasis on precision rather than brute strength.

- Durability: While robust enough for its intended tasks, it is not designed to handle the heavy torque required for pipe work.

- Pipe Wrench:

- Materials: Constructed from heavy-duty forged steel to withstand high-torque applications.

- Durability: Built for heavy-duty use, making it a long-lasting tool for plumbing and construction tasks.

4. Ergonomics and User Experience

- Spud Wrench:

- User Experience: Lightweight and ergonomically designed for tasks that require a fine touch.

- Comfort: Its design reduces user fatigue during precision work.

- Pipe Wrench:

- User Experience: Heavier and bulkier due to its robust construction.

- Comfort: While effective in delivering torque, prolonged use can lead to fatigue unless proper ergonomic features (like cushioned handles) are incorporated.

5. Maintenance Considerations

- Spud Wrench:

- Maintenance: Typically requires less frequent maintenance due to its lighter use and less demanding applications.

- Care Tips: Keep it clean and store it in a dry place to prevent rust.

- Pipe Wrench:

- Maintenance: Requires regular cleaning to remove grease and debris that can accumulate in its serrated jaws.

- Care Tips: Periodically oil the adjustable mechanism and inspect for wear to maintain its grip efficiency.

Choosing the Right Tool for the Job

When deciding whether to use a spud wrench or a pipe wrench, it’s important to consider the specific requirements of your project. Here are some tips to help you choose:

Consider the Task

- If you are dealing with small, delicate fasteners where precision is key (such as in automotive repairs or machinery maintenance), a spud wrench is the better choice.

- If the task involves turning large, cylindrical objects like pipes that require significant torque, then a pipe wrench is the appropriate tool.

Analyze the Work Environment

- For confined spaces where a bulky tool might not fit, the slim design of a spud wrench can be advantageous.

- Conversely, if you have ample space and need the extra power, a pipe wrench’s design will serve you better.

Frequency of Use and Ergonomic

- For tasks that require repetitive motions or extended periods of work, consider the ergonomic design of the tool. A spud wrench’s lighter build may reduce fatigue during prolonged use.

- For heavy-duty work, investing in a well-designed pipe wrench with ergonomic handles can help mitigate the physical strain.

Budget and Quality

- Both tools come in various price ranges. However, if you anticipate frequent use in demanding environments, opting for a high-quality pipe wrench may be more cost-effective in the long run.

- For occasional precision work, a good-quality spud wrench will likely meet your needs without breaking the bank.

Maintenance and Safety Tips for Wrench Users

Regardless of whether you choose a spud wrench or a pipe wrench, proper maintenance and safety practices are essential to prolong the life of your tool and ensure your personal safety.

Maintenance Tips

- Regular Cleaning:

Keep your wrenches free from dirt, grease, and debris. Wipe them down after each use, especially if you’re working in environments with a lot of contaminants. - Lubrication:

For adjustable tools like the pipe wrench, regular lubrication of the moving parts can prevent rust and ensure smooth operation. - Inspection:

Periodically inspect your wrenches for signs of wear or damage. Look for cracks in the metal, worn-out serrations, or any issues with the adjustable mechanisms. - Proper Storage:

Store your tools in a dry, secure location. Use toolboxes or wall-mounted racks to keep them organized and to prevent accidental damage.

Safety Tips

- Use the Correct Tool:

Always choose the wrench that is appropriate for the task at hand. Using the wrong tool can lead to slipping or damage to the workpiece, increasing the risk of injury. - Wear Protective Gear:

When working with heavy-duty tools, it’s wise to wear safety glasses and gloves to protect against metal shards or accidental impacts. - Maintain a Stable Work Environment:

Ensure that your work surface is stable and that you have proper lighting. A steady work area minimizes the risk of accidents, especially when applying high torque. - Follow Manufacturer Guidelines:

Adhere to any usage or maintenance instructions provided by the manufacturer to avoid voiding warranties or compromising safety.

By following these maintenance and safety tips, you can extend the life of your spud or pipe wrench and maintain a safe working environment.

Conclusion

Both the spud wrench and the pipe wrench are essential tools, each designed with a specific purpose in mind. The spud wrench excels in precision tasks where a delicate touch is necessary—ideal for automotive maintenance, machinery repairs, and small-scale adjustments.

On the other hand, the pipe wrench is built for strength and versatility in heavy-duty applications, particularly in plumbing and construction work.

When choosing between the two, consider the nature of your project, the environment in which you are working, and the level of precision or torque required. While a spud wrench may be perfect for tasks that demand accuracy, a pipe wrench is indispensable when high torque is needed to handle larger, cylindrical objects like pipes.